Spring clamp terminal blocks

The product family consists of terminal blocks that are based on a spring clamp connection. By spring clamp connection, we mean an electrical connection that is created by clamping an individual of an individual, isolated conductor using a spring. It is suitable for solid wires and multi-wire strands of 0.08 – 2.5 mm2 rated section and enables:

direct terminal without pre-treatment of conductor

direct terminal with splice protection

indirect terminal via wire end sleeve or pin cable shoe

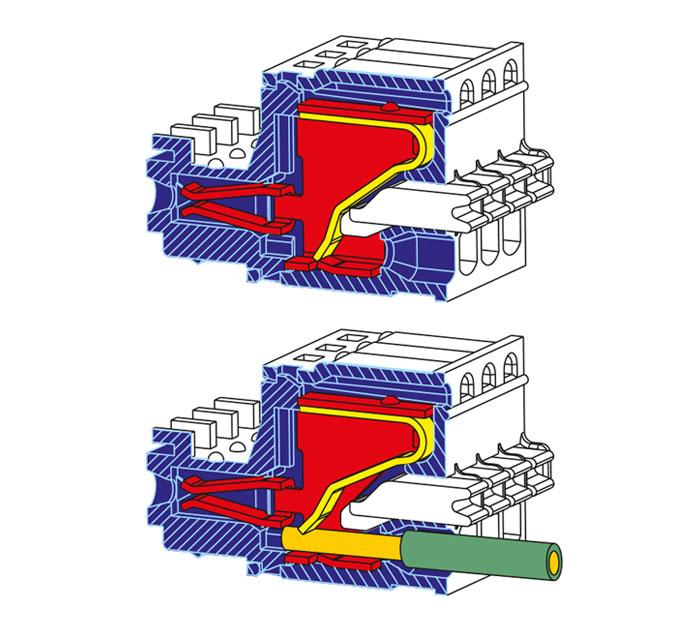

Spring clamp terminal block with cage clamp (with and without eccentric lever)

with eccentric lever open terminal chamber in the delivery status

with eccentric lever tool-less connection of the conductors

very short assembly times

the closed power system inside the terminal block prevents pressure from being applied onto the circuit board at the time of connection

gas-proof connection at the terminal point

can be installed in the housing

the spring adapts automatically to changed conductor sections

Spring clamp terminal block with leaf spring

solid wires can be connected by simple insertion without actuation

stranded wires and thin solid wires are connected using a standard screwdriver

short assembly times

gas-proof connection at the terminal point

sequenceability of different colors

can be installed in the housing

the spring adapts automatically to changed conductor sections

One technology - several options

Reflow-compatible components

METZ CONNECT offers a wide range of spring clamp terminal blocks in reflow-compatible designs. The demand for reflow-compatible components is constantly growing thanks to ever increasing degrees of automation in the production processes.

Tape & Reel

"Tape & Reel" is the name given to a taped form of packaging. The aim of this packaging variant is to automate production processes. The components are packed in a blister tape and welded with a protective foil. This tape is then wound round a reel. Taping corresponds to DIN EN 60286.

Printing options

We offer individual printing of your terminal blocks. Different colors, figures or symbols, anti-clockwise or clockwise, legible or bottom up depending on the technical feasibility. Ink-jet print and pad printing are available as methods. Design your individual terminal block with us.

Product overview