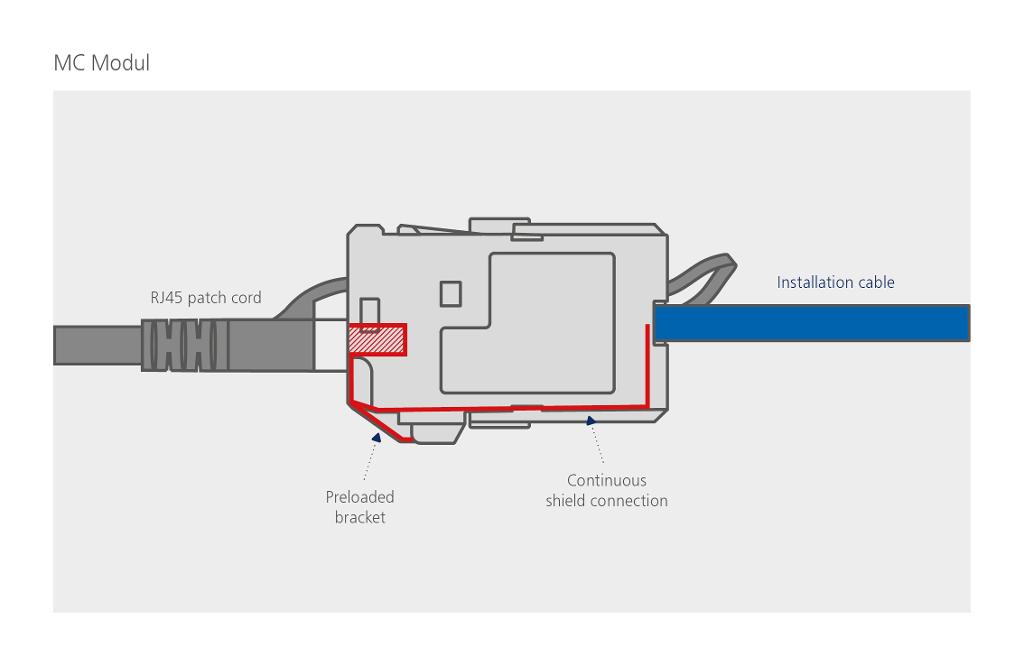

MC Modul or Keystone

The difference between the two installation cut-outs

Our modules are available with different installation cut-outs (MC Modul and Keystone).

In different applications (such as wall outlets, patch panels, module frames, DIN rail housing REGplus, underfloor units, etc.), it is essential that the installation cut-out for the application is compatible with the installation cut-out for the module. Therefore, when choosing a module, it is important to consider its individual installation cut-out. The product specification provides all of the information you need to do so.

Installation cut-out – MC Modul design

Installation cut-out – Keystone design

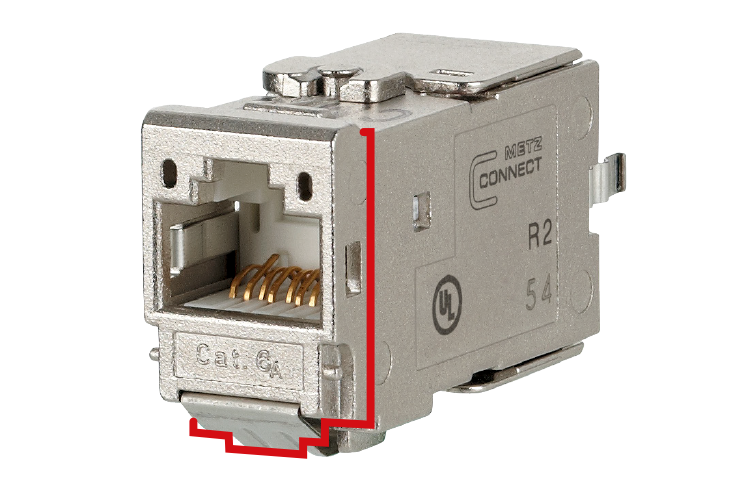

MC Modul installation cut-out – benefits at a glance

the shape and associated installation type allow the module to be installed and removed securely and easily in applications (such as wall outlets, patch panels, ...)

applications can be manufactured from a wide range of different materials (plastic, stainless steel ...)

the pre-tensioned bracket made of highly conductive material runs through the entire module without any material changes

a consistently stable shielded connection is ensured for years, with minimal contact resistance from the connected installation cable to the inserted RJ45 patch cord

patch panels based on the MC Modul installation cut-out also ensure consistently low contact resistances, from the cable shielding to the module frame